Voice of noise

Noise pollution is becoming more and more of an environmental issue. We are surrounded by noise from a variety of sources. Noise affects our health and behaviour, whether it is loud noise for short periods or a continuous high level of noise over the long term.

In the face of an increasing number of studies estimating the effects of noise pollution, we need to begin to view noise as a criterion in the design of cargo handling equipment.

Ambient noise level is measured in decibels (dB) above a reference pressure. Measurement is normally by frequency weighting filter, the most common being the A-weighting scale, in which results are denoted dB(A). The other extreme – total silence – can be equally disturbing. We are not used to that, either. Fortunately we rarely find ourselves in a place entirely devoid of sound. In theory, silence equates to 0 dB(A); in practice, the human ear considers levels up to 30…40 dB(A) as total silence. The upper end of the scale, 93…97 dB(A), might include aircraft taking off. The noise level at a container terminal typically starts from 70 dB(A). It is worth noting that the dB(A) scale is logarithmic; this means we can already detect a reduction of even a few dB(A).

Noise measurement

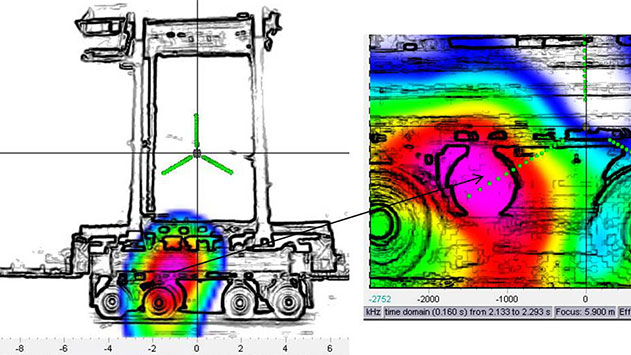

Noise is usually measured by the noise meter giving a value under various operating conditions; the overall average value can then be calculated using the operations profile. Together with peak values, this gives a point of comparison among the various machines or systems used. Another, more specific, means of identification is to use a ‘noise camera’. These ‘pictures’ reveal the exact sources and levels of noise emitted by machines, and thus create a firm basis for potential corrective action to reduce noise level (see image).

How do we reduce noise pollution?

Once noise sources have been identified, the work can start. Continuous noises or the overall noise level need to be damped using various means, such as:

- Elastic damping material or plates where needed

- Additional absorption material around noise sources

- Tightening of all loose items, clamps, handrails, etc.

- Tightening of all hose and cable lead-in to stop noise leakages

- Improved insulation of various machinery spaces

- Exhaust silencer cover made from damping material

- Even partial covering of open noise sources to steer noise in the desired direction

- Rubber support between materials, such as gratings and frames

- Selection of sliding surface materials to include noise damping properties

Sudden sharp noises can be reduced by changes in the way a machine operates. For example, ‘soft landing’ features can be programmed into a machine lowering containers. Instead of a full-speed sudden stop, the machine slows down at the last moment, both reducing noise and sudden deceleration that could damage the cargo.

Silent terminal… or whispering giants

The noise pollution challenge for terminals is that many are now surrounded by heavily populated housing or industrial areas. Pressure builds to limit operating hours or use other means to bring down the level of noise.

Environmental pressure towards zero emission machinery indicates – and recent development confirms – that fully electric equipment and terminals are within reach. For several equipment types a full electrical version is gaining market share. Over the next decade we will see the first fully electric terminals, and this will also have a major impact on noise pollution.

Over the next decade we will see the first fully electric terminals, and this will also have a major impact on noise pollution.

The feeling will be much the same as with hybrid cars using batteries, or when walking along Chinese roads full of electric scooters. The only noise will come from the airflow around the vehicle, and possibly from the whirl of the electric engine. For people, this might be dangerous where there are machines on the move, with one of the two main senses for recognising danger rendered ineffective. Whispering giants, such as ASCs and RTGs, together with an electric horizontal transport system, will reduce noise pollution in terminals to the absolute minimum.